What makes a difference on Quality of impactor blow bars.

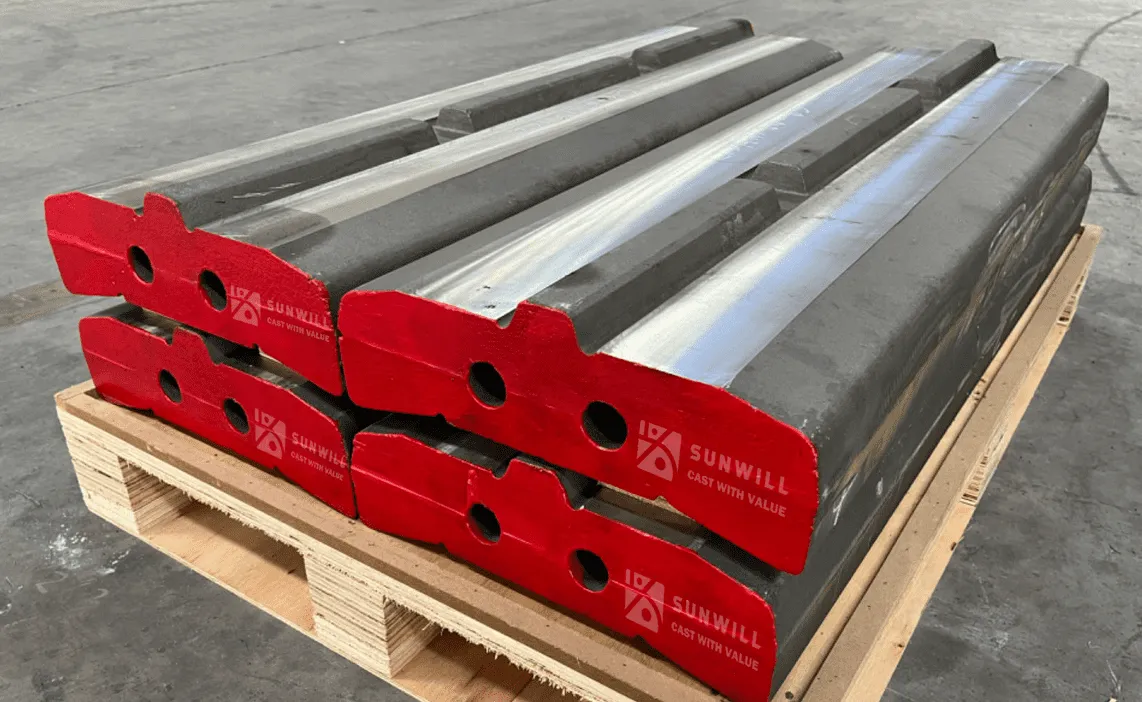

When it comes to Quality of blow bar, the wear life is always the most considered but also reliability is as same important. A good blow bar should last long and maintain an even wearing face till the end of wear life, at the same time doesn’t break. What is essential to make a good blow bar? Below is the answer.

Correct ingredients of material

This is the basis and foundation of a good blow bar. The elements must be at a correct percentage by weight and the hazard chemicals such as S and P must be as low as possible. Some elements such as Mo and Ni are must be added within a correct range to achieve the targeted property. Also, the scrap content in material should be at a decent grade and not exceed a certain percentage. However, higher grade of material will push up the cost of material and make a big difference on the cost of blow bar.

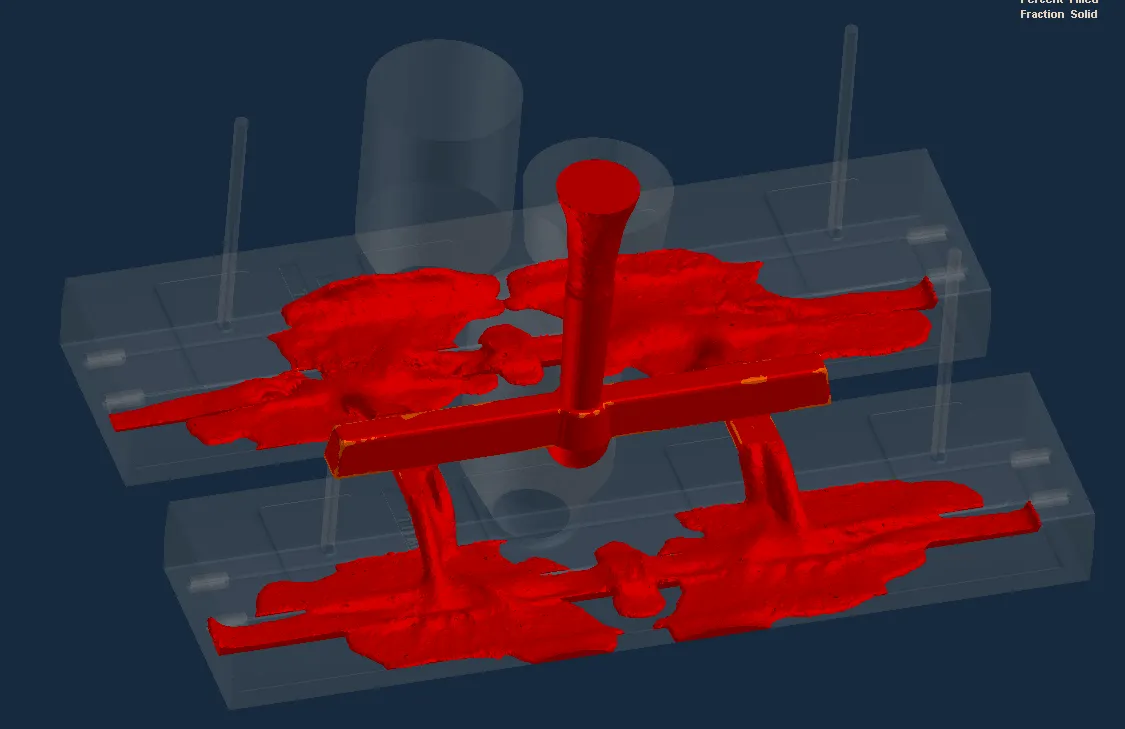

Correct and good design of casting system

This is always ignored by foundry. A good casting system will maximumly reduce the defects or failures in the casting. This is always relying on foundry engineers’ experience, knowledge and research on metallurgy.

Mold quality and design

A blow bar is born in a mold. A good mold should be robust in material, correct for size and easily operated for molding. As explained above, an integrated mold is always the first choice for reliably creating the blow bar even though is more expensive.

Pouring

Pouring is not simply dumping the melt steel liquid into the sand flask. A correct pouring with correct speed and precise temperature control is very important to secure the quality of casting. A small error of pouring will lead to big defect or failure inside the casting, especially for the ceramic blow bars which is extremely sensitive to metallurgy and temperature.

Head treatment

Head treatment shapes the mechanical characteristics of a blow bar. A correct heat treatment will empower the blow bar with excellent anti-wear performance against abrasion as well as good toughness against impact. Heat treatment will make a big difference on the performance of blow bars. Heat treatment is the art of temperature which also heavily rely on the experience, knowledge and operation control of engineers.

Machining

Machining is always difficult on the blow bars as the base material is always hard for milling. A good machining will make the correct fitting size and sufficient contact areas in rotor of impact crusher.

Inspection

In foundry no one is 100% sure that every casting is done perfect. Inspection is the only way to find out the unqualified ones and make sure every piece of blow bar that handed over to customer is in correct size and good quality. Inspection must be carried out everywhere in the whole process of manufacturing.

Foundry management

A high-level foundry management is to get production timely organized, correctly and safely operated, and every product is made in accordance with requirements and with unqualified product is internally rejected. All is all, a high-level managed foundry is more likely to get quality secured and reliable in a long time.

Quality is not simply created by using the good material. It’s a combination of all above and more factors. To make a good blow bar, all things must be done 100% correct.

For more technical spec and application advice, please visit www.sunwillmachinery.com

Watch the foundry video for blow bar manufacturing Sunwill Machinery – YouTube