OUR VISION

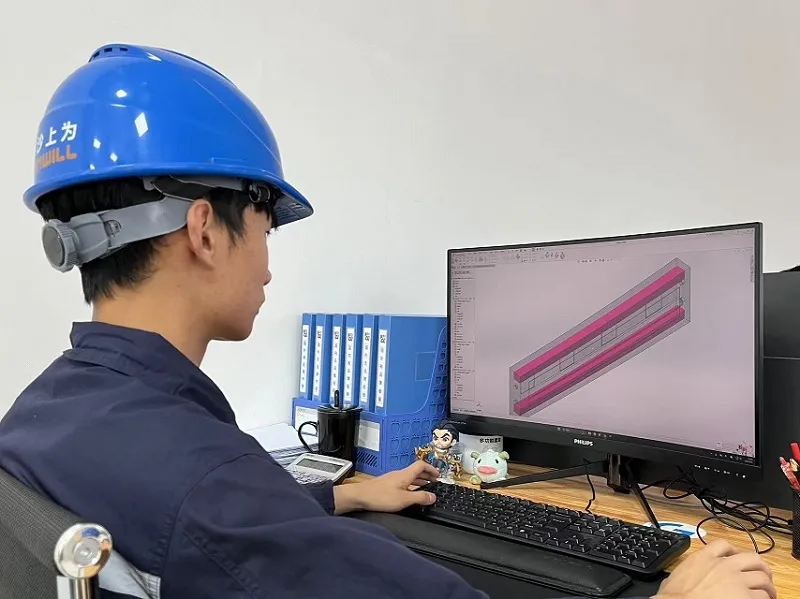

With the background of metallurgy engineering and over two decades experience as a technical head officer in wear parts foundries, Mr. Lin and his Engineering team started Sunwill Machinery in 2021 dedicated to provide better wear parts and solutions for customers in Quarry, Aggregates, Mining, Cement, Recycling and Construction industries.

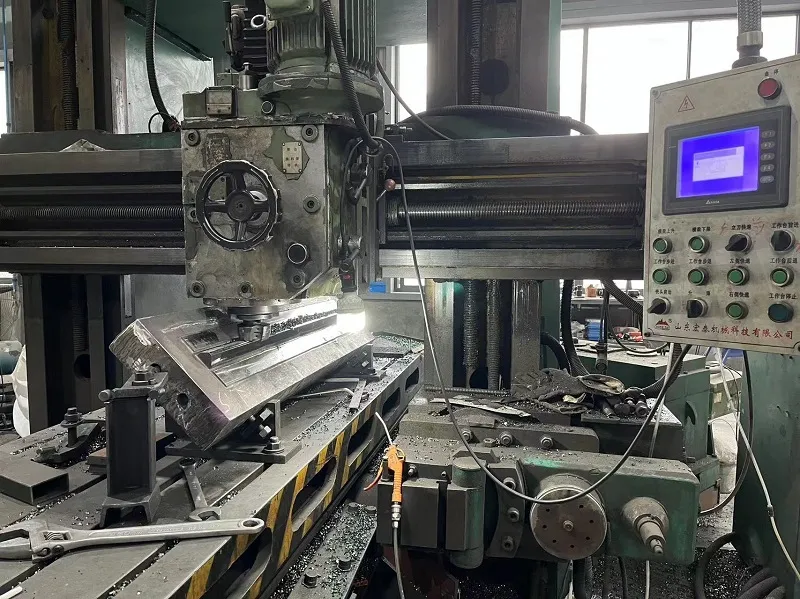

The company has been developing very fast into a trusted, reputed supplier of MMC (Metal Matrix Composite) and DHT wear parts worldwide, striving to be one of the world-leading brands for wear parts and wear solutions in the industry.