How is impact crusher blow bar made & What makes a difference on Quality?

Blow bar is the essential wear parts for impact crusher (HSI). Normally the blow bars are made by casting in foundry in a few types of alloy steel below to suit the various working conditions of crushers.

Chrome steel

Feature: excellent wear resistance but brittle.

Typical applications: secondary or tertiary crushing with abrasive and small size feed and no tramp goes iron into feed.

Chrome steel matrix with ceramic honeycomb inlaid

Feature: an upgraded chrome steel blow bar with better wear performance but same brittleness.

Typical applications: where the chrome steel blow bars are used.

Martensitic alloy steel

Feature: lower wear performance but tougher than chrome steel

Typical applications: concrete recycling crushers or crushing with large feed or a little tramp iron content.

Martensitic alloy steel matrix with ceramic honeycomb inlaid

Feature: an upgraded martensitic steel blow bar with better wear performance but same toughness.

Typical applications: where the martensitic alloy steel blow bar is used.

Manganese steel

Feature: the lowest wear performance but toughest

Typical applications: primary limestones crusher or crushing with largest feed or big tramp iron into feed.

Manganese steel with Titanium carbide columns inserted

Feature: an upgraded manganese steel blow bars with better wear performance but same toughness.

Typical applications: where the manganese steel blow bar is used.

Customized steel

Feature: special chemicals or mechanical property for specific working conditions.

Blow bars are always made with sand casting started from a timber or steel mold. Some foundry makes it with lost-foam casting from a pattern cut from foam. Normally the blow bars made by sand casting have better metallurgy quality and finer finishing but the cost is relatively higher than blow bars made from foam casting. Blow bars made in martensitic steel must be made by sand casting because it has a lower carbon content and very sensitive in metallurgy, while the foam casting will have a big contamination in the metal from the foam burning.

Below is the manufacturing process of blow bars made by sand casting:

Mold/Pattern preparation.

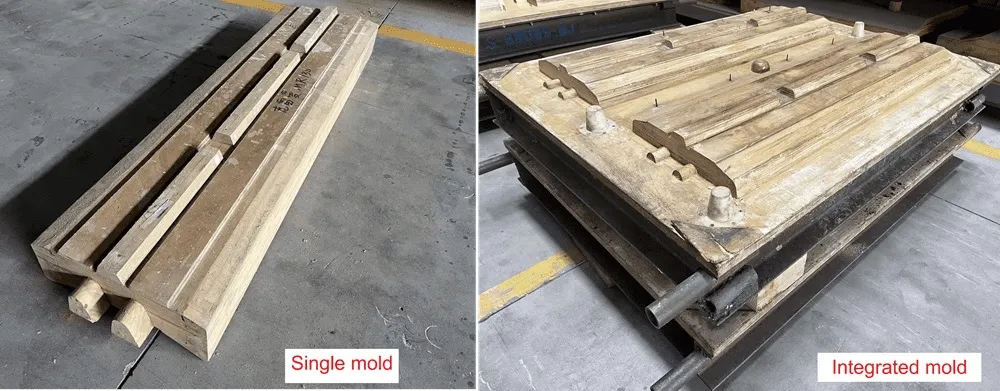

The blow bars mold is normally made from timber and created by CNC machine. The molds are generally sorted in two types – single mold & integrated mold. The single mold is just the core part of casting created, while the integrated mold is a whole casting system created including the holding frames and positioning pins. The integrated mold is more expensive than single mold but it is more friendly for operation and more reliable for the pattern quality.

Molding

A blow bar pattern is created in the sand flask with the mold. After a series of processing including cleaning, coating and drying, the pattern is ready for pouring. In addition, the ceramics or titanium carbides are fixed in the pattern if it is a ceramic or Tic inserted blow bar.

Pouring

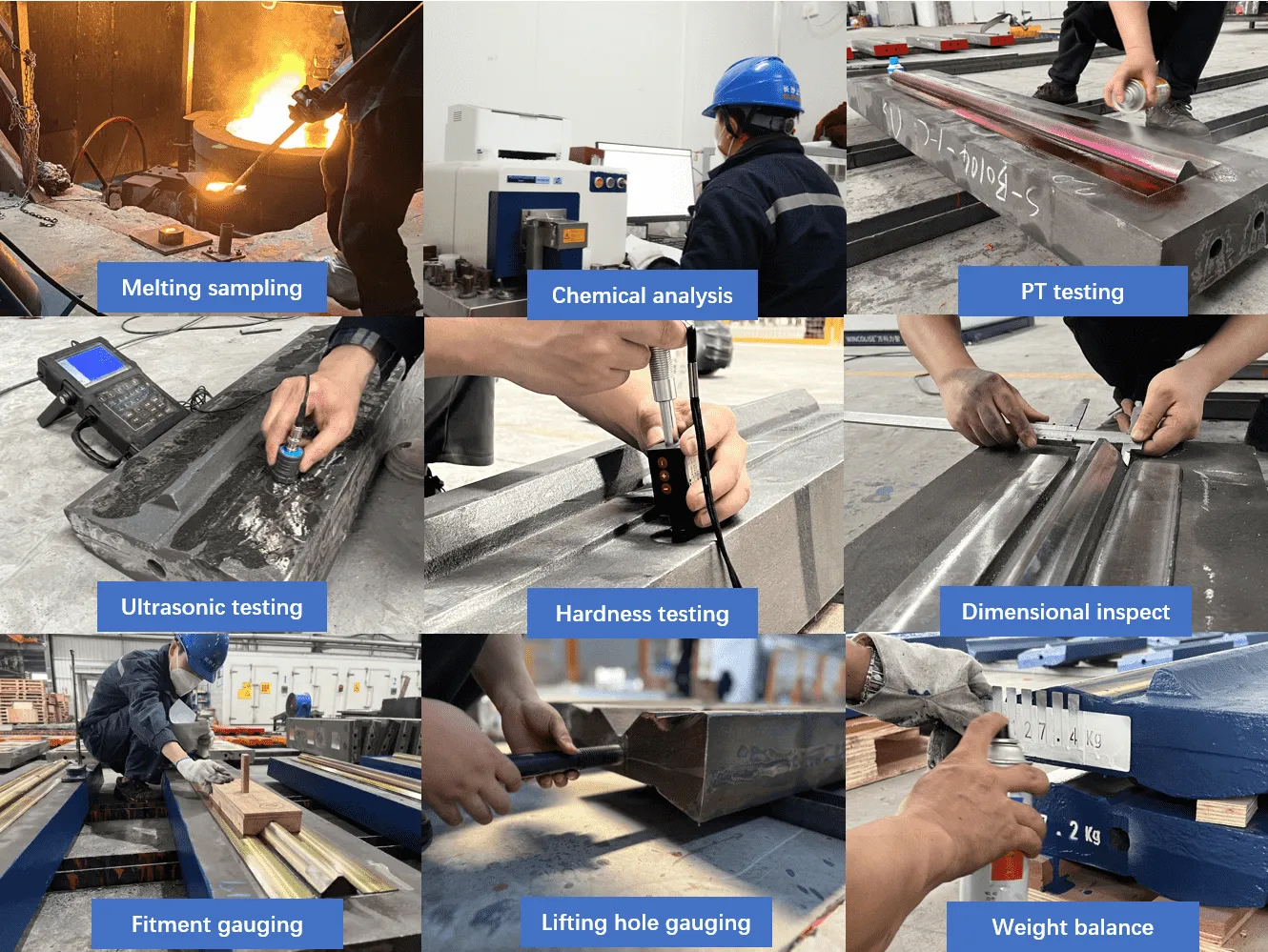

The raw materials are mixed up and melt in the furnace. Many types of chemical additives are added and some physical measures is necessary to purify the metal liquid. Before and during pouring the temperature of steel liquid must be precisely controlled and pouring must be continuous for a blow bar. Also, the samples of metal must be prepared for every melting for chemical analysis and traceable records.

Cleaning

After the casting is cooling down and solidified, the sands, ingates and risers on blow bar billet is cleaned and removed.

Heat treatment

The blow bar billets are treated with several loops of heating up and cooling down to get the proper mechanical properties. Heat treatment is a crucial part to secure the quality and performance of blow bars. The temperature and heating time must be precisely set based on the material and size of blow bar, and rate of heating and cooling also must be correct.

Grinding and machining

Heat-treated blow bars are blasted and ground with the burrs and edges removed. The blow bar must be carefully ground to avoid any cracks due to grinding heat. Machining on the fitting areas on some types of blow bar must be done to ensure it is straight and flat for fitment in rotor of crushers.

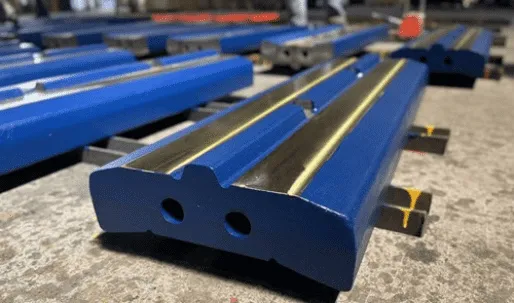

Coating and packing

Blow bars are always coated for anti-rust purpose also in different color for materials identification. Robust and seaworthy package is also necessary for the final packing.

Inspection

Inspection is an important part of blow bar manufacturing. Inspection must be in place in every procedure of manufacturing from raw materials to final packing, including chemical analysis, surface defect, inner quality, dimension, hardness, microstructure, toughness, finishing, color, labeling and more if necessary.

Foundry management

A high-level foundry management is to get production timely organized, correctly and safely operated, and every product is made in accordance with requirements and with unqualified product is internally rejected. All is all, a high-level managed foundry is more likely to get quality secured and reliable in a long time.

Quality is not simply created by using the good material. It’s a combination of all above and more factors. To make a good blow bar, all things must be done 100% correct.

For more technical spec and application advice, please visit www.sunwillmachinery.com

Watch the foundry video for blow bar manufacturing Sunwill Machinery – YouTube